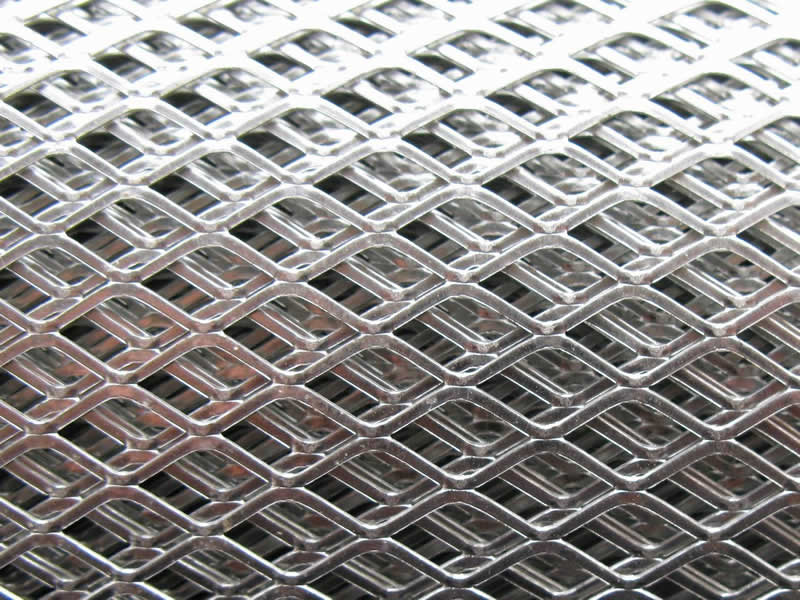

Expanded Metal Mesh

| Material: | Carbon steel plate |

| Feature: | Anti-slip surface |

| Application: | buildings and construction |

More Details

Product Description

Expanded metal mesh is also called pulled plate wire mesh. A rigid piece of metal that has been slit and drawn into an open mesh pattern in a single operation. It is stronger, lighter in weight and more rigid than the original base metal.

Expanded metal mesh material are carbon steel plate, stainless steel, galvanized steel, aluminum, aluminum foil, lead, nickel plate, titanium, aluminum-magnesium alloy panels. Conventional mesh is formed in a diamond pattern. It has other pattern of hexagonal, round, triangle, scale-like opening.

Features and benefits of expanded metal mesh:

- The mesh is formed from a single piece of metal

- The process is not wasteful of material

- Higher strength-to-weight ratio than sheet metal

- Anti-slip surface

- Excludes and retains simultaneously

- Premium reinforcement properties

- Practical and effective screening

- High efficient conductor

- Super corrosion resistance

Expanded metal mesh has a wide range of uses, graceful shapes , strong processing capability. A major advantage of expanded is that the mesh is formed from a single piece of material and the process is not wasteful and therefore cost effective.

Main use: metal surface treatment and after processing, are widely used in large venues, both inside and outside decorative, aerospace, petroleum, chemical industry, metallurgy, medicine, paper making, filtration, breeding, packing, mechanical facilities, protection, handicraft manufacturing, high-grade speaker grille, children’s seat, baskets, basket, highway protection, and heavy machinery, boilers, oil mines, locomotives, tonner steamship, work platform, staircase, walkway. Also can be used for construction, highway and bridge as reinforced use.

The term of expanded metal mesh:

SWD (Short Way of the Diamond) is the distance from the middle of the bond on one side to the middle of the bond on the opposite side.

LWD (Long Way of the Diamond) is the distance across the largest dimension of the diamond measured halfway between the diamonds.

SWO (Short Way of the Opening) is the width of the opening of the shortest side of the diamond. SWO does not include the strand width, where SWD (Short Way of the Diamond) does.

LWO (Long Way of the Opening) is the length of the opening of the longest side of the diamond. LWO does not include the strand width, where LWD (Long Way of the Diamond) does.

Strand and Bond Expanded metal is composed of strands and bonds. Strands form the sides of the expanded metal openings. Bonds are where the strands intersect. In other words, the bond is where each diamond shaped opening is connected with the next opening.

Thickness is the measurement from the top surface to bottom surface of the expanded metal piece.

Expanded metal Roll: that the specific length and width of the wound into the roll of steel mesh.

Expanded metal sheet: The expanded metal that show specific length and width.

| Specification of Expanded Metal Mesh | ||||||

| Sheet Thickness | Opening in Width mm | Opening in Length mm | Stem | Roll Width mm | Roll Length mm | Weight kg/m2 |

| 0.5 | 2.5 | 4.5 | 0.5 | 0.5 | 1 | 1.8 |

| 0.5 | 10 | 25 | 0.5 | 0.6 | 2 | 0.73 |

| 0.6 | 10 | 25 | 1 | 0.6 | 2 | 1 |

| 0.8 | 10 | 25 | 1 | 0.6 | 2 | 1.25 |

| 1 | 10 | 25 | 1.1 | 0.6 | 2 | 1.77 |

| 1 | 15 | 40 | 1.5 | 2 | 4 | 1.85 |

| 1.2 | 10 | 25 | 1.1 | 2 | 4 | 2.21 |

| 1.2 | 15 | 40 | 1.5 | 2 | 4 | 2.3 |

| 1.5 | 15 | 40 | 1.5 | 1.8 | 4 | 2.77 |

| 1.5 | 23 | 60 | 2.6 | 2 | 3.6 | 2.77 |

| 2 | 18 | 50 | 2.1 | 2 | 4 | 3.69 |

| 2 | 22 | 60 | 2.6 | 2 | 4 | 3.69 |

| 3 | 40 | 80 | 3.8 | 2 | 4 | 5.00 |

| 4 | 50 | 100 | 4 | 2 | 2 | 11.15 |

| 4.5 | 50 | 100 | 5 | 2 | 2.7 | 11.15 |

| 5 | 50 | 100 | 5 | 1.4 | 2.6 | 12.39 |

| 6 | 50 | 100 | 6 | 2 | 2.5 | 17.35 |

| 8 | 50 | 100 | 8 | 2 | 2.1 | 28.26 |